KFL Supermarket, VIC

Project Description

The primary requirement was to provide effective heating, cooling, and humidity control for staff and customers while integrating seamlessly with the existing building management system. Limited plant space and previously inaccessible areas presented a significant challenge, requiring a bespoke AHU design.

A critical aspect of the project was the recovery of waste heat without compromising cooling performance. Achieving this required precise control of ventilation, humidity, and thermal comfort, including demand-controlled ventilation based on indoor CO₂ sensors. Additionally, the system needed to maintain the correct indoor air temperatures, manage defrost cycles, and deliver reliable, efficient heating across the store.

Project Requirements and Challenges

The primary requirement was to provide effective heating, cooling, and humidity control for staff and customers while integrating seamlessly with the existing building management system. Limited plant space and previously inaccessible areas presented a significant challenge, requiring a bespoke AHU design.

A critical aspect of the project was the recovery of waste heat without compromising cooling performance. Achieving this required precise control of ventilation, humidity, and thermal comfort, including demand-controlled ventilation based on indoor CO₂ sensors. Additionally, the system needed to maintain the correct indoor air temperatures, manage defrost cycles, and deliver reliable, efficient heating across the store.

MHIAA’s Solution

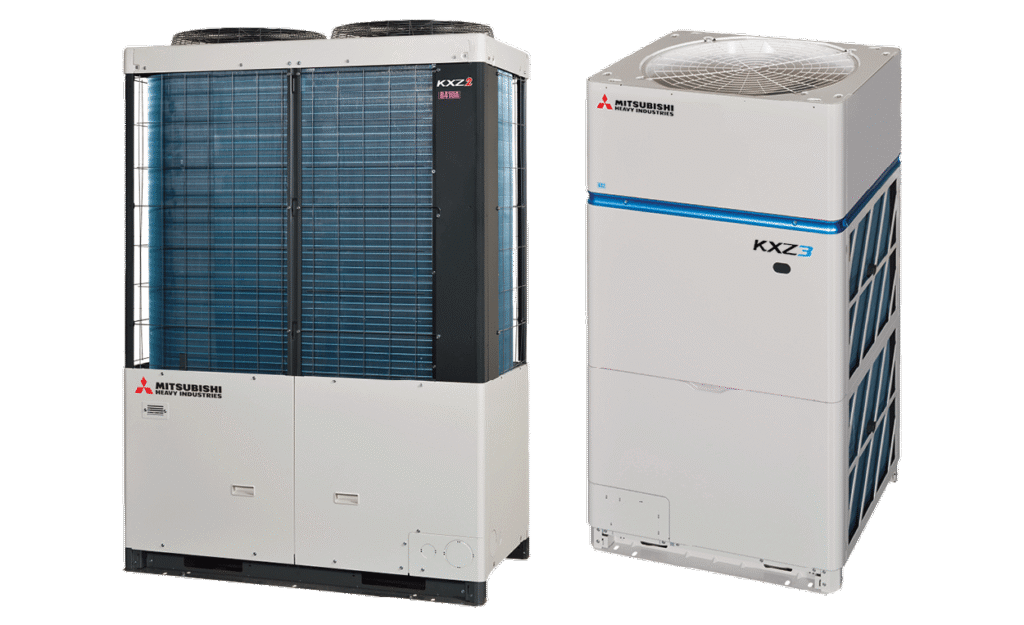

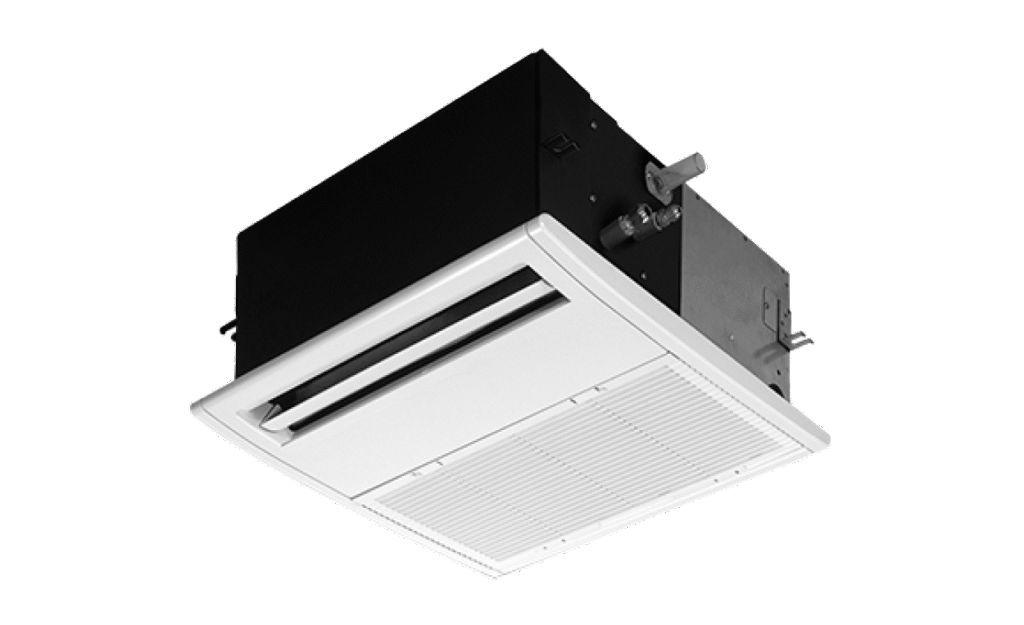

The custom-built AHU featured new generation EC plug fans, which delivered improved energy efficiency and lower noise levels compared to earlier generations. Ventilation rates were controlled based on indoor CO2₂ levels, optimising air quality while minimising energy use.

The AHU incorporated an advanced heat recovery strategy, recovering waste heat from refrigerated cases via a heat exchange coil located before the VRF coil. This configuration enhanced refrigeration performance by desuperheating and reducing compressor lift, while also providing the first stage of heating for the supply air, reducing the VRF heating load and minimising defrost cycles.

The VRF and heat recovery coils were divided into upper and lower sections, enabling flexible modes of operation such as upper coil heating combined with lower coil cooling for precise dehumidification. A world-first staged solenoid arrangement was implemented for the heat recovery coils, providing highly refined capacity control and maximising waste heat utilisation.

The system was designed to supply 6,000 L/s of air through the AHU, with the VRF cooling coil providing 112 kW total capacity (86 kW sensible) and a sensible heat ratio of 0.76, while the heat recovery coil could provide up to 70 kW of recovered waste heat. This configuration satisfied the majority of the store’s heating requirements using recovered energy, significantly reducing reliance on active heating.

The completed installation delivered substantial energy savings, improved thermal comfort, and precise humidity control across the retail areas. It reduced both refrigeration and VRF operating loads and provided a flexible, maintainable AHU plant suited to future servicing and upgrades. The project demonstrates the capability of MHIAA’s flexible AHU solutions to support innovative, site-specific refrigeration integration strategies, achieving superior performance outcomes in demanding retail environments.